CNC wood machines are versatile tools capable of processing a wide variety of wood types. Here’s an overview of the main categories and specific examples of woods that can be effectively machined using CNC technology.

Types of Wood Suitable for CNC Machining –

1. Hardwoods

Hardwoods are derived from deciduous trees and are known for their density and durability. They are often used in furniture, cabinetry, and decorative projects. Common hardwoods include:

– Oak: Strong and moisture-resistant, ideal for outdoor furniture.

– Maple: Dense and durable, suitable for heavy-duty applications.

– Cherry: Offers a beautiful finish and is versatile for various projects.

– Walnut: Known for its rich color and strength, favored in high-end woodworking.

– Beech: Odorless and strong, great for kitchen utensils.

2. Softwoods

Softwoods come from coniferous trees and are generally easier to machine than hardwoods. They are commonly used in construction and furniture making. Notable softwoods include:

– Pine: Affordable and easy to work with, often used in furniture.

– Cedar: Weather-resistant with a pleasant aroma, suitable for outdoor applications.

– Fir: Known for its strength and stability, often used in structural applications.

– Spruce: Lightweight and versatile, commonly used in construction.

3. Engineered Woods

Engineered woods are manufactured products that combine wood fibers or veneers with adhesives. They offer stability and uniformity, making them popular choices for CNC machining:

– MDF (Medium Density Fiberboard): Smooth surface and consistent density, ideal for detailed cutting and shaping.

– Plywood: Made from layers of wood veneer, offering strength and stability; available in various grades.

CNC wood machines can process a wide range of materials, including both hardwoods and softwoods, as well as engineered woods like MDF and plywood. The choice of wood depends on the specific application requirements, desired aesthetics, and the capabilities of the CNC machine being used. Each type of wood presents unique characteristics that can impact the machining process, making it essential to select the appropriate material for optimal results.

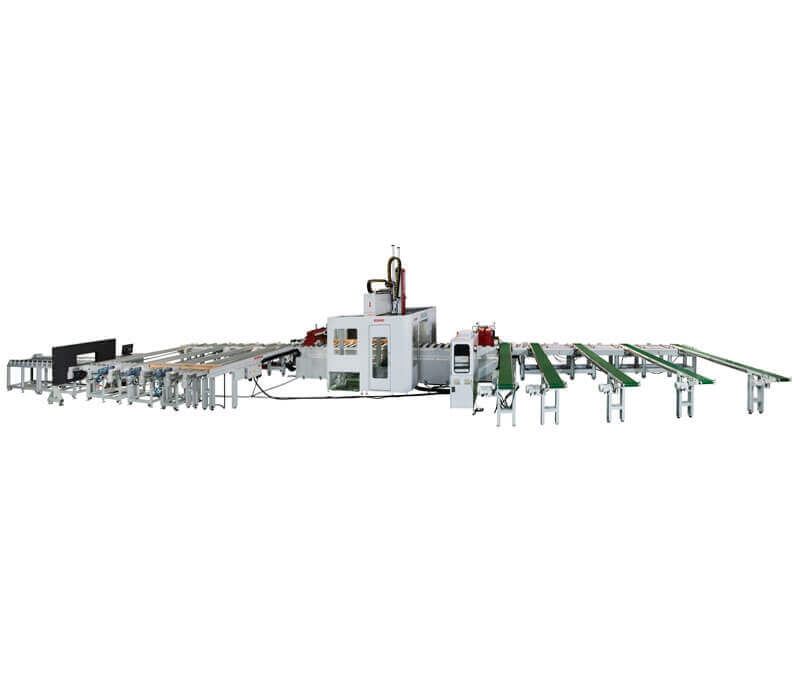

Among the leading manufacturers in this field is Boarke Machine Co., Ltd. a company with over 30 years of experience in the CNC woodworking machine industry. Boarke is committed to innovation and sustainability, specializes in a range of CNC wood machines designed for diverse woodworking needs:

– 6 Axis CNC Machining Center: Ideal for complex shapes and high-speed machining tasks.

– 5 Axis Double Column Machining Center: Offers enhanced precision for intricate designs.

– Wide Belt Sanding Machine: Provides a smooth finish on large surfaces efficiently.

– Top and Bottom Sander: Ensures uniform sanding on both sides of the material.

For those looking to elevate their woodworking operations with advanced technology, Boarke Machine Co., Ltd. is your reliable partner. Contact us today to learn more about our innovative solutions tailored to your needs!