The automotive rubber manufacturing industry is undergoing significant transformations due to the rapid rise of electric vehicles (EVs). As the automotive landscape shifts towards electrification, manufacturers are adapting to meet the unique demands of this new technology. This blog explores the key trends, challenges, and innovations in automotive rubber manufacturing as it responds to the growing prominence of electric vehicles.

Key Trends in Automotive Rubber Manufacturing

- Specialized Rubber Components for EVs

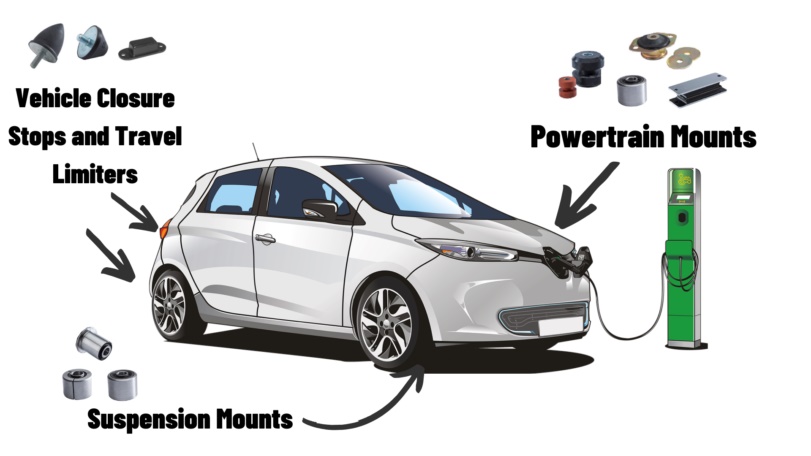

Electric vehicles require specialized rubber components tailored to their unique operational needs. For instance, battery packs demand high-performance seals and gaskets to ensure safety and prevent leaks. Additionally, components such as electric motors and inverters necessitate rubber parts that can withstand high temperatures and vibrations. The evolution of these specialized components is crucial for maintaining the efficiency and reliability of EV systems.

Moreover, as EVs incorporate more complex electronic systems, manufacturers are focusing on producing rubber parts that can integrate seamlessly with these technologies. Innovations like smart seals with sensors to monitor wear or potential leaks are becoming increasingly common, enhancing safety and performance.

- Lightweight and Durable Materials

To enhance range and efficiency, electric vehicles focus on reducing weight. Consequently, rubber manufacturers are developing lightweight yet durable rubber compounds that meet these requirements. Advanced technologies such as nanotechnology are being employed to enhance properties like strength, flexibility, and heat resistance. These innovations ensure that rubber components can perform effectively under the demanding conditions present in electric vehicles.