Aluminum extrusion is a process that shapes aluminum by forcing it through a die. It produces complex and lightweight parts that are strong and uniform. The parts are treated to improve their properties and can be customized to fit specific needs. Custom aluminum extrusion fabrication is a fast and cost-effective way to create high-quality components for various industries. It has many benefits, such as corrosion resistance, thermal and electrical conductivity, and aesthetic appeal. Custom aluminum extrusion fabrication is a key technology for modern manufacturing.

What is Aluminum Extrusion

Generated with Bing AI Image Creator

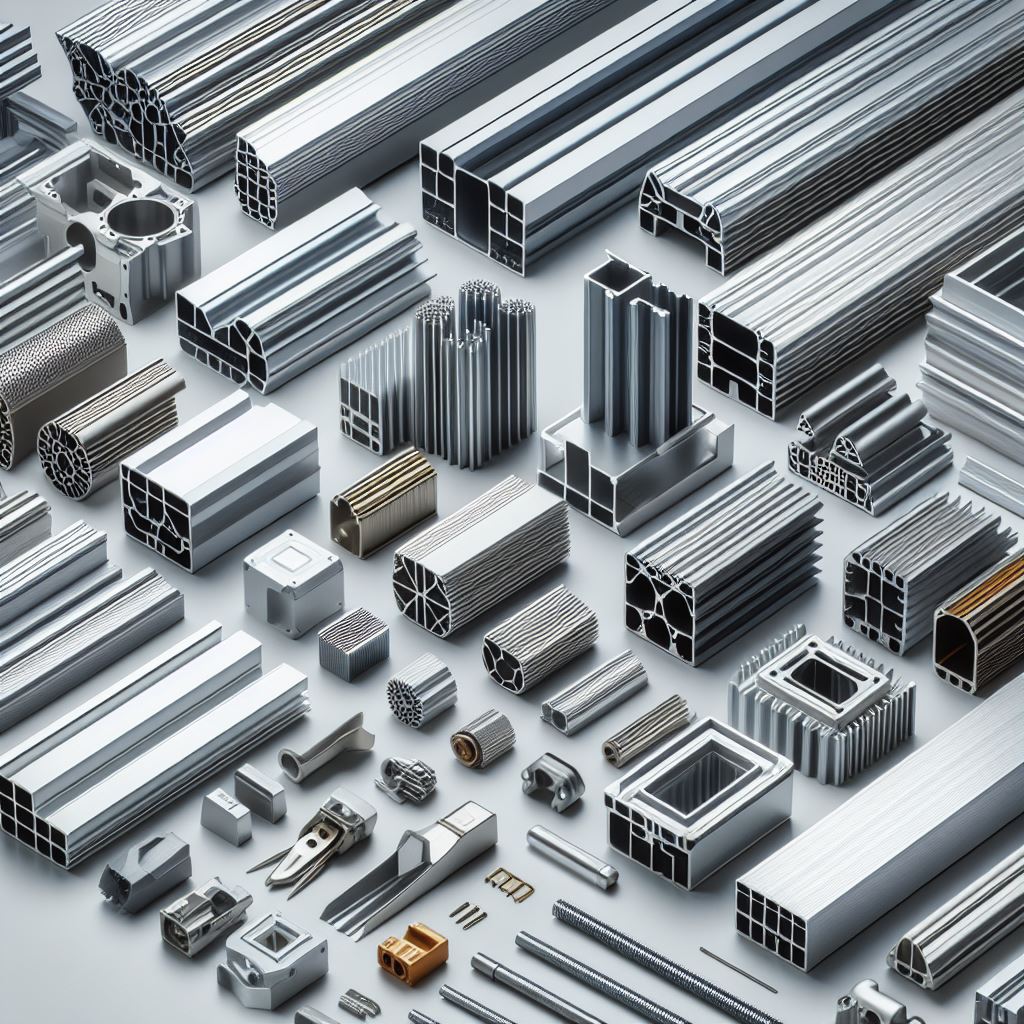

Aluminum extrusion is an industrial process that shapes aluminum by forcing it through a die with a specific cross-sectional profile. This method allows for the production of complex and lightweight components that are structurally strong and consistent in shape. The extrusion process begins with the selection of the appropriate aluminum alloy, such as 6061 or 7075, which is then heated and pushed through the die. The extruded material is cooled, hardened, and subjected to various treatments like T5 or T6 to achieve the desired mechanical properties. This process is ideal for creating a wide range of products, from simple angles and channels to intricate custom profiles.

Customization and Precision in Aluminum Extrusion Fabrication

Custom aluminum extrusion fabrication stands out for its ability to produce tailor-made solutions for specific industry needs. By designing a unique die, manufacturers can create profiles that perfectly match the requirements of their applications. The advanced technology involved in the extrusion process, including 3-axis and 5-axis milling machines, ensures high precision and quality. The material’s thickness, dimensions, and component weight can be controlled with tight tolerances, resulting in parts that meet the most demanding specifications. This level of customization and precision is invaluable for industries ranging from automotive to construction, where specialized components are essential.

The Benefits of Custom Aluminum Extrusion Fabrication

The benefits of custom aluminum extrusion fabrication are numerous and impactful. This process allows for on-demand delivery of extrusion parts, facilitating cost-effective series production. The use of aluminum in extrusion offers a lightweight yet durable solution, with the added advantage of being corrosion-resistant. Custom extrusions can also be designed to optimize thermal and electrical conductivity, making them suitable for applications such as electrical systems and cooling devices. Furthermore, surface treatments like anodizing and powder coating enhance the appearance and longevity of the components. With its combination of efficiency, versatility, and quality, custom aluminum extrusion fabrication is a cornerstone in modern manufacturing.

Precision Aluminum Extrusion by DMS Group

DMS Group is a leading provider of aluminum extrusion services, offering customization options using different aluminum alloys like 6061 and 7075. They can handle a wide range of material thicknesses and component weights, catering to both complex and large-scale extrusion needs.

DMS utilizes cutting-edge extrusion methods to ensure high accuracy and quality in the production process. They also provide various surface treatments like anodizing and powder coating to enhance the performance and appearance of components.

DMS Group is dedicated to delivering extrusions that meet the highest quality standards and adhere to your delivery schedule. Their service is tailored to your exact specifications, from design to the final product. They employ the latest extrusion technology and work with different aluminum series to create lightweight and durable parts.

With a commitment to precision, DMS Group guarantees tolerances up to 0.1 mm. They also offer heat treatment options like T4, T5, and T6 to optimize material properties for specific applications. Their goal is to provide flawlessly crafted solutions that are delivered on time to support your project.

Visit and find out more : https://www.dmsgroup-tw.com/