In today’s fast-paced manufacturing landscape, the demand for precision and efficiency is more pronounced than ever. As industries continue to evolve, the need for high-volume production solutions that do not compromise on quality has become paramount. Enter the world of Small Hole Electrical Discharge Machining (EDM) Drilling Machines—an innovative solution that is transforming the way manufacturers approach complex drilling tasks.

Small Hole EDM Drilling Explained

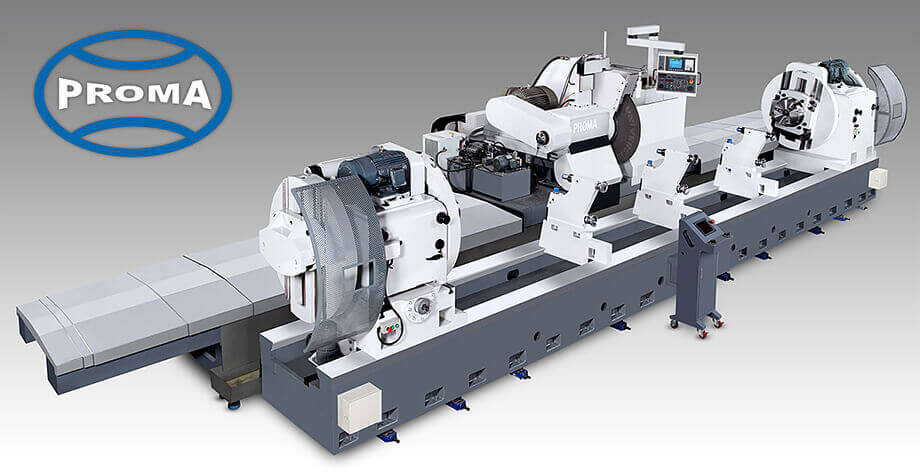

Small hole EDM drilling is a specialized process designed to create precise holes in hard materials. This method is particularly effective for applications requiring intricate details such as turbine blades, fuel injectors, and starter holes for wire EDM. The technology relies on electrical discharges to erode material, allowing it to cut through even the toughest metals with unparalleled accuracy and speed.

Why Choose Small Hole EDM Machines?

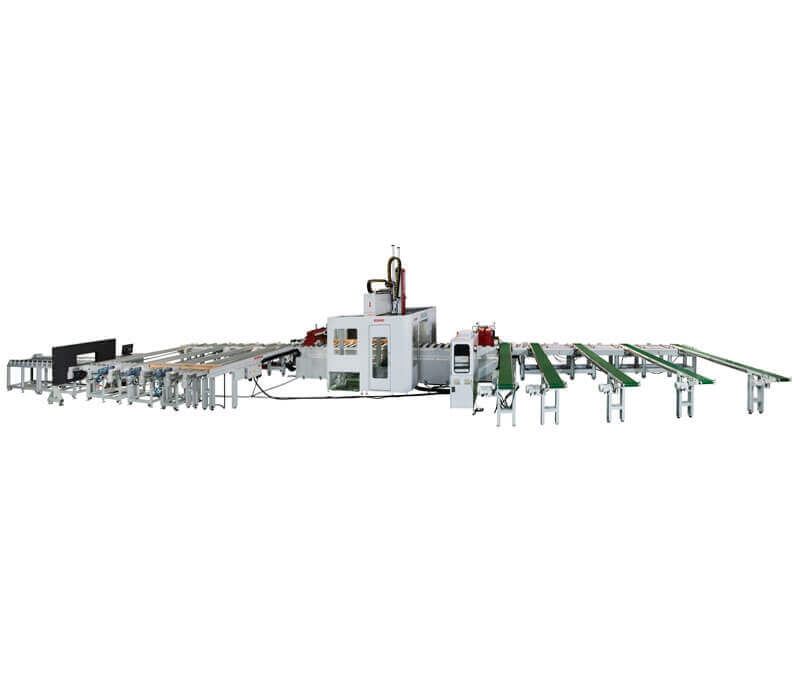

- Precision and Accuracy: The River 35 NC Small Hole EDM Drilling Machine by Ocean Technologies is engineered to deliver unmatched precision. With its digital control mechanism and HP1+(plus) high-speed circuit, it ensures stability and reliability in every operation.

- Versatility: From creating coolant holes in cutting tools to vent holes in plastic molds, small hole EDM machines are versatile, adapting to a wide range of industrial applications.

- Efficiency: Time is money in the manufacturing industry. Small hole EDM machines like the River 35 are designed to enhance drilling speed, significantly reducing production time without compromising quality.

- Cost-Effectiveness: Investing in a small hole EDM drilling machine can lead to substantial cost savings. By improving efficiency and reducing material waste, these machines can lower overall production costs.

Applications Across Industries

Small hole EDM drilling machines are utilized across various sectors, including aerospace, automotive, and medical device manufacturing. For instance, in aerospace, these machines are crucial for producing turbine blades that demand high precision and durability. In the automotive industry, they play a key role in fabricating fuel injectors that require intricate hole patterns.

Ocean Technologies: Pioneering Small Hole EDM Solutions

Ocean Technologies Co., Ltd. is a leading CNC electric discharge machine manufacturer from Taiwan, stands at the forefront of small hole EDM innovation. With a commitment to quality and performance, their River Series, including the River 35 small hole EDM, offers tailored solutions to meet the unique needs of high-volume production environments. By leveraging advanced engineering and cutting-edge technology, Ocean Technologies provides machines that are not only reliable but also adaptable to future manufacturing challenges.

As the manufacturing industry continues to advance, the adoption of small hole EDM drilling machines will undoubtedly increase. For businesses aiming to enhance precision, efficiency, and cost-effectiveness in their production processes, these machines offer a strategic advantage. Explore Ocean Technologies’ range of small hole EDM solutions and discover how they can revolutionize your manufacturing operations. Contat Ocean Technologies Now!