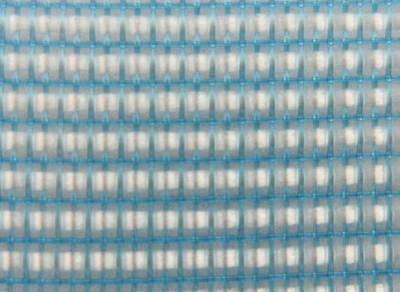

Elastane was developed as an alternative to rubber in the 1950’s and is a thermoplastic polyurethane synthetic fiber. The unique property of this elastomer, as a result of its randomly coiled polymer structure made up of a mix of stiff and flexible segments, is that it can be stretched 500% or more without breaking or permanently deforming. Giving it the well-known characteristic of the ability to revert to its original shape after being stretched. The long amorphous segments in elastane create the elastic properties and the short rigid segments provide the structure when the fiber is stretched and released. Elastane has the highest stretch tension of all textile raw materials.

Elastane is soft, lightweight and abrasion resistant. Elastane is used where a high degree of permanent elasticity is required, as in tights, sportswear, swimwear and in woven and knitted fabrics. Adding elastane just for couple of percent makes fabrics more comfortable to wear. Elastane is always used in a blend with other fibers.

Elongation on an elastane yarn is much higher than on a more rigid yarn, like polyamide on Lymed fabric. When stretching a knit, the elastane yarn would practically never get to its limits of the elongation. This means, in most cases, that the elastane would not determine the ultimate elongation in the knit- determination is made by the rigid yarns in the fabric. Also, the construction of the knit has effect on the stretchability- looser the knit, stretchier the fabric.

More elastane content in a fabric does not mean that the fabric will have more stretch. By increasing the elastane content in the fabric, more resistance to stretch is created using the elastomeric material. More elastane means more powerful fabric.

Maw Chawg Enterprise Co., Ltd. can offer some related information about elastane yarn and other textiles to you. Welcome to visit Maw Chawg’s website to see what textile series they can offer you!

Article Source: http://lymed.fi/en/ufaqs/tuotteissanne-on-paljon-elastaania-miksi-ja-miten-se-vaikuttaa-tuotteisiin/

Article Source: https://www.wools.co.uk/elastane-lycra-.html

Established in 1979, Mountop Precision began by providing clients with heat-treatment finishing work, specializing in heat-treatment of high-speed steel and steel molds. Denison hollow vane just is the products that we can offer you.

Established in 1979, Mountop Precision began by providing clients with heat-treatment finishing work, specializing in heat-treatment of high-speed steel and steel molds. Denison hollow vane just is the products that we can offer you.